Carbon steel elbow introduction

What is carbon steel elbow?

Carbon steel elbow is a metal pipe that changes the direction of the pipe on a carbon steel pipe. The connection method is wired and welded. According to the angle, there are 45°, 90° and 180° three commonly kinds, other abnormal angle such as 60°. Our company mainly provide carbon steel, stainless steel and alloy steel elbows based on international standards.

classification:

First of all, according to its radius of curvature, there are long radius elbows and short radius elbows. Long radius elbow refers to its radius of curvature equal to 1.5 times the outside diameter of the pipe, that is, R=1.5D. Short radius elbow means that its radius of curvature is equal to the outside diameter of the pipe, that is, R=1.0D. (D is the diameter of the elbow and R is the radius of curvature. D can also be represented by multiples.)

In addition, according to the pressure level, there are about 17 kinds of pipe standards, including: Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS; Sch80, Sch100, Sch120, Sch140, Sch160, XXS. The two most commonly used are STD and XS.

Finally, according to the angle of the elbow, there are 45°, 90° and 180° elbows. The executive standards are GB/T12459-2005, GB/T13401-2005, GB/T10752-1995, HG/T21635-1987, D-GD0219 and so on.

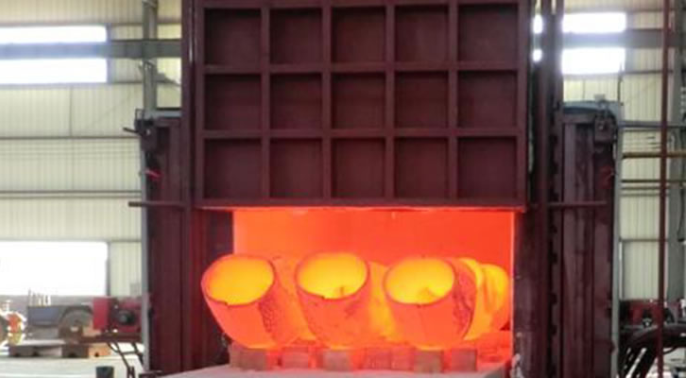

Carbon steel elbow heat treatment:

The carbon steel elbow needs normalizing + tempering heat treatment and machining port. The wall thickness needs to leave a allowance for burning and processing. The general allowance is 10% ~ 20% of the theoretical wall thickness of the elbow. The smaller the ratio of the wall thickness to the section diameter, the better the fitting performance with the mold.

The higher the austenitizing temperature of the material, the higher the heating temperature; The higher the high temperature yield limit of the material, the higher the heating temperature. Medium frequency induction heating, the highest temperature of WB36 steel is 850 ~ 900 ° C, A335P22 steel is 900 ~ 950 ° C, and the heating temperature of A335P91 material is 900 ~ 1000 ° C.

The temperature measurement method is the combination of fixed far-infrared thermometer and manual far-infrared thermometer. The temperature distribution is an important process parameter, which is directly controlled by the shape of the induction ring and the relative position between the induction ring and the mandrel head. The radial distribution of temperature along the mandrel head is low, medium and high. When the heating temperature is high, the wall thickness of the stamping elbow increases.

The principle of determining the propulsion speed is that the main compressive stress of the inner wall of the elbow is less than the yield limit of the material at this temperature. And the elongation of the outer wall of the elbow is less than the maximum elongation of the material at this temperature. The material has high permeability, permeability and medium frequency power, and the propulsion speed is fast.

Why choose us to buy elbow?

Metleader have been passed several certificates including ISO9001: 2008, ISO14001, OHSAS18001, CE certificate, one member of supplier system of Sinopec, and CNPC.

All in all, we will provide the best service to our customers. welcome your inquiry timely salesmanager@metleader.com .