4 Types of Pipe Elbows and Their Uses

Contents

- Preface

- Welded elbow

- Forged elbows

- Seamless elbows

- Adjustable elbows

- Comparison of elbow materials

- Summary

Preface

In industrial pipelines, suitable elbows are very important. Whether it is connection or conversion, you need to choose a reasonable elbow.

If you are a professional who talks about elbows pipe, then you should know the importance of elbows in industrial pipelines.

In this article, we will explore the four types of elbows. We will also explore the economic benefits and applications of these four types of elbows in depth.

Next, let’s take a look.

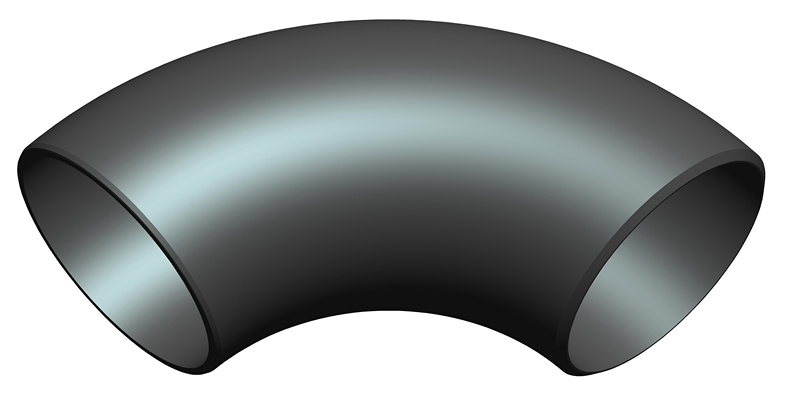

Welded elbow

Welded elbows, due to their excellent structural strength, are often used in piping systems that withstand high pressure or have special requirements.

What is a welded elbow

Welded elbows are mainly composed of two parts: one is the pipe elbow part, which is responsible for changing the direction of the fluid; the other is the flange or welded joint, which is used to ensure a stable connection between the elbow and other parts of the pipeline system.

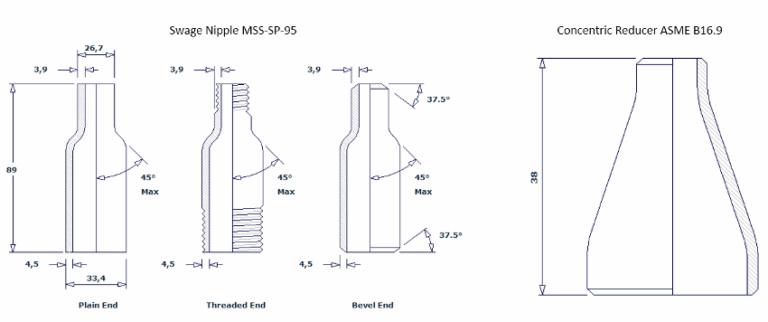

Types of elbows

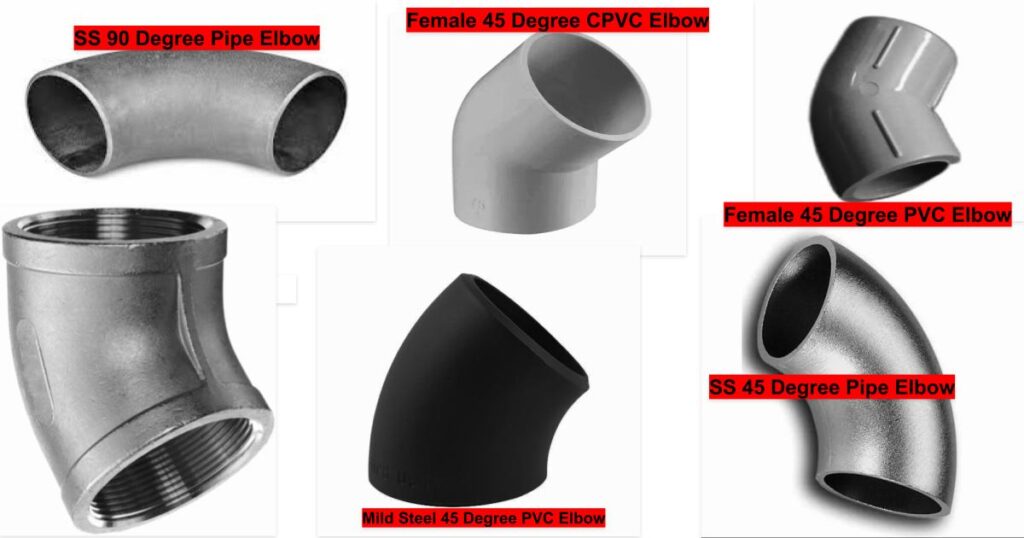

According to the angle, there are mainly long elbows and short elbows of 45 degrees, 90 degrees and 180 degrees, and also some special angles such as 60 degrees, 100 degrees, etc.

In addition, according to the size of the pipe diameter, it can also be divided into large elbows and small elbows, with a wide range of pipe diameters, usually from DN15 to DN1200.

Applications of welded elbows

Welding elbows are widely used in many industries, such as petroleum, chemical industry, shipbuilding, papermaking, metallurgy, electricity, and pharmaceuticals.

In the pipeline systems of these industries, welding elbows play a vital role, not only enabling smooth turns of pipelines, but also effectively changing the flow direction of fluids.

Forged elbows

Forged elbows are pipe fittings made by forging technology.

They have a 90-degree or 45-degree bend shape and are used to change the direction of the pipeline.

What is a forged elbow

Forged elbow is a kind of pipe fitting which is processed by metal billet through forming processes such as stamping and extrusion under high temperature and high pressure.

Standards for the use of forged elbows

- Material standards

Forged elbows are generally made of carbon steel, alloy steel, stainless steel and other materials, and their materials should comply with national standards or industry standards. - Size standards

The size of forged elbows should comply with national standards or industry standards. When using, attention should be paid to its matching with the pipeline. Only when the size is appropriate can the tightness of the connection be ensured. - Working pressure standards

The working pressure of forged elbows should comply with national standards or industry standards, and shall not exceed the working pressure range specified in the standards, otherwise it may cause accidents.

Applications of forged elbows

Forged elbows are a high-strength, high-pressure pipe connection method that is suitable for various pipe systems that need to be connected and are commonly used in petrochemical, electric power, construction, metallurgy and other industries.

Seamless elbows

Seamless elbows are made of a whole piece of metal, with no seams and various shapes, covering specifications from 0.3 mm to 650 mm. They are crucial in fields such as oil drilling and aviation manufacturing.

What is a seamless elbow

Seamless elbow is a kind of pipe connector, which consists of three parts: pipe body, pipe cover and elbow.

Among them, the pipe body is a section of the pipe with a certain length and diameter, which is used to connect with other pipe joints; the pipe cover is to close one end of the pipe body to allow liquid or gas to flow smoothly; the elbow is to change the direction of the pipe body to adjust the flow direction of the pipeline.

How to use seamless elbows

Determine the installation location and direction of the seamless elbow;

Regularly inspect and maintain the seamless elbow;

Use appropriate tools and methods for installation;

Precautions for seamless elbows

- When using seamless elbows, pay attention to the environment and medium in which they are used to select appropriate materials and models.

- Before installing seamless elbows, they should be cleaned and disinfected to ensure that they meet hygiene requirements.

- During use, pay attention to the temperature and pressure of the pipeline to avoid thermal deformation or rupture of seamless elbows.

- When installing seamless elbows, pay attention to their connection method and tightening strength to ensure that they have good sealing and stability.

Adjustable elbows

Adjustable elbows have the advantages of flexibility and strong adjustability, and can be widely used in chemical, petroleum, pharmaceutical and other industries.

However, when using them, attention should be paid to correct installation and maintenance to ensure the safety and stability of the pipeline connection.

What is an adjustable elbow

Adjustable elbow is an elbow that can adjust the bending angle as needed, and is often used in pipe connections.

It is generally composed of a pipe connection flange, an adjustable shaft and an elbow.

Installation of adjustable elbows

The installation of the adjustable elbow needs to be judged and operated according to the specific situation. The general steps are as follows:

- Install the flange at the pipe connection. Note that the flange model should be the same as the pipe;

- Insert the adjustable shaft into the flange;

- Insert the elbow into the adjustable shaft;

- Use bolts to fix the elbow to the flange.

Adjustment of adjustable elbows

The adjustment of the adjustable elbow needs to be achieved by adjusting the adjustable shaft. The general steps are as follows:

- Loosen the bolts between the elbow and the flange;

- Adjust the length of the adjustable shaft to make the elbow reach the required angle;

- Tighten the bolts between the elbow and the flange.

Precautions for adjustable elbows

- When installing the adjustable elbow, make sure the flange model is the same as the pipe, and tighten the bolts evenly and one by one;

- When adjusting the adjustable elbow, make adjustments according to actual needs and do not over-lengthen or shorten the adjustable shaft;

- If the adjustable shaft does not reach the required length, check whether it is loose or has other problems.

Comparison of elbow materials

| Material | Corrosion Resistance | Pressure and Temperature Tolerance | Cost | Installation Ease | Typical Applications |

| Stainless Steel | Excellent | High | High | Requires skilled labor for welding | High-pressure, high-temperature, and corrosive environments |

| Carbon Steel | Moderate | High | Low | Can be welded or threaded | Construction and infrastructure |

| Copper | Good | Moderate | Moderate | Can be soldered or brazed | Plumbing and heat exchange |

| Galvanized Steel | Good | High | Low-Moderate | Can be welded or threaded | Outdoor and industrial |

| Brass | Good | Moderate | Moderate | Easy to install | Small-scale plumbing |

| PVC | Good | Low | Low | Easy to install | Water supply and drainage |

| CPVC | Good | Moderate-High | Low-Moderate | Easy to install | Hot water and industrial fluid handling |

| PPR | Good | Moderate | Moderate | Easy to install | Plumbing and heating |

| Fiberglass and Resin | Excellent | Moderate | Moderate | Can be installed with adhesives | Corrosive environments |

Summary

Reasonable selection of elbows can ensure the safety and reliability of engineering projects.

As professionals, we should understand the direct differences between different types of elbows to facilitate us to make better choices.

I hope this article can provide some ideas and suggestions.