Swage nipples vs Reducers: A Beginner’s Guide

Contents

Preface

Are swage nipples and reducers the same product? This question is often asked. In fact, these are two completely different products. Understanding their differences will help us better choose the product that suits us.

In the pipeline system, swage nipples and reducers are both very important, but there are also some differences between the two. Let’s learn about swage nipples and reducers through this article.

What is a Swage nipples

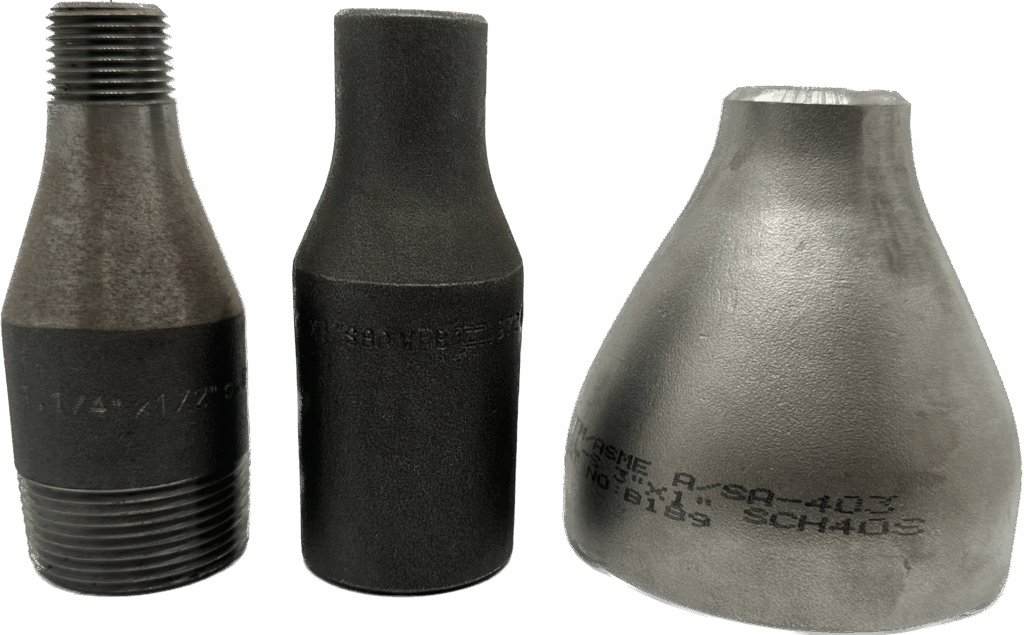

A swage nipple is a pipe connection device, which is generally made by welding two pipes with different diameters, or it can be made by forging.

The function of a swage nipple is to connect two pipes of different diameters together, and to connect parts of different diameters and shapes in the pipe to achieve pipe connection.

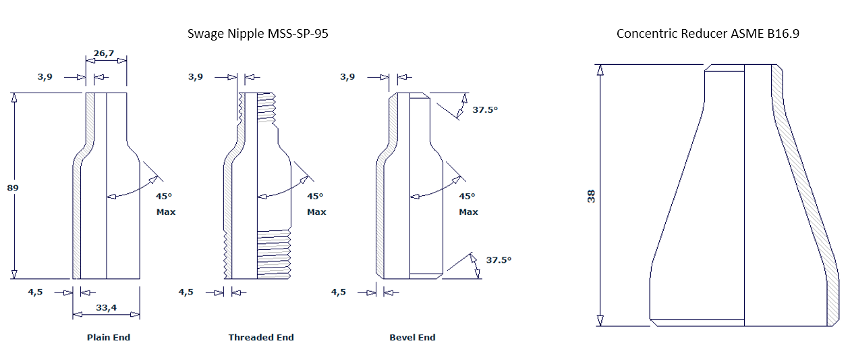

Types of Swage nipples

Concentric Swage Nipple: These fittings have an even reduction in diameter, keeping the centerlines aligned at both ends. Ideal for applications that require a smooth, continuous flow.

Eccentric Swage Nipple: These fittings have an uneven reduction, with the centerline of the small end offset relative to the large end. They are used to prevent problems such as cavitation or uneven flow by maintaining a specific pipe alignment.

Characteristics of Swage nipples

The appearance of the swage nipple is similar to a “bottleneck shape”, and the diameters of the two ends are different, so it is called a “reducing nipple”.

Applications of Swage nipples

Swage Nipples have the advantages of less material consumption, low cost, easy manufacturing and installation, etc.

They are often used in pipeline systems in chemical, petroleum, natural gas, food and other industries.

The materials of reducing nipples are generally carbon steel, stainless steel, alloy steel, etc.

Connection methods of Swage nipples

There are many ways to connect swage nipples, including socket welding, butt welding, flange connection, etc.

Among them, socket welding is a commonly used connection method and also a strong connection method.

What is a reducer

A reducer is a pipe connector with the same diameter at both ends, but different connection methods.

One end is a flat end that needs to be connected to a flange, and the other end is a threaded interface that needs to be connected to a threaded pipe.

Types of reducer

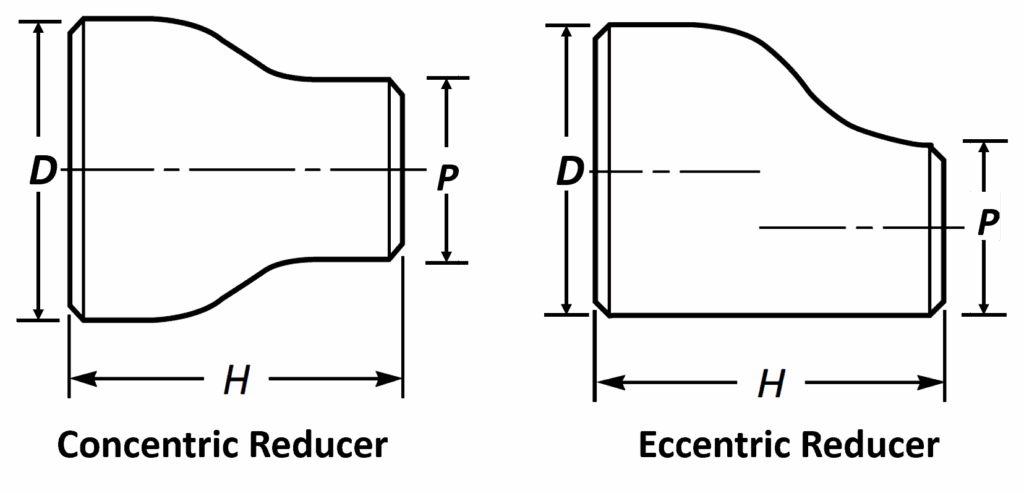

Reducers are divided into concentric reducers and eccentric reducers.

The ends of the pipe joints of concentric reducers are on the same axis, while the ends of the pipe joints of eccentric reducers are not on the same axis.

According to the shape, reducers can also be divided into circular reducers, rectangular reducers, square reducers and rectangular connecting pipes with twisting direction.

Characteristics of reducer

- Accurate size: The diameter and wall thickness of the reducer are precisely processed, and the size is accurate, which can meet the needs of different occasions.

- Tight connection: The connection method of the reducer adopts thermal expansion or compression, and the connection is tight, which is not easy to leak air or liquid.

- High strength: The strength of the reducer is higher than that of ordinary steel pipes, and it can withstand greater pressure and load.

- Corrosion resistance: The inner wall of the reducer is specially treated to prevent medium corrosion and has a long service life.

Applications of reducer

Reducers are mainly used at the pipe diameter change point, so that pipes of different diameters can be connected smoothly.

Reducers are key components for connecting pipes to ensure the smooth operation of the system.

They are widely used in many fields, such as chemical, petroleum, pharmaceutical, etc., to ensure the smooth operation of the pipeline system.

Manufacturing process of reducer

The manufacturing method of reducers is usually selected by user requirements and corresponding standards.

Reduction forming, expansion pressing or reduction plus expansion forming are common forming processes for reducers;

Reducers can be made seamless or welded, and usually small diameter ones are made seamless.

Swage nipples vS reducing pipe

- Different connection methods: The two ends of the reducing short pipe have different diameters and are often used to connect pipeline systems of different sizes; while the two ends of the reducer have the same diameter, but the connection methods are different.

- Different application scenarios: The reducing short pipe is mainly used to adjust the flow rate and flow rate in the pipeline system to meet the system requirements; while the reducer is mainly used to connect pipeline systems of different specifications and materials.

- Different use conditions: The reducing short pipe needs to connect pipes of the same material, or use the intermediate short pipe section to connect pipes of different materials; while the reducer can connect pipes of different materials.

- Different advantages and disadvantages: The reducing short pipe can adjust the flow rate and flow rate, but the connection is complicated; the reducer is simple to connect, but the flow rate and flow rate cannot be adjusted.

Summary

Although both reducers and reducers are pipe connectors, they are different in application scenarios, connection methods, usage conditions, advantages and disadvantages.

In practical applications, appropriate connectors should be selected according to actual conditions to ensure the normal operation of the pipeline system.

I hope that after reading this article, you will have a full understanding of reducers and reducers.