Exporting Carbon Steel Pipe Fittings: A Complete Guide to International Standards & Certifications

Contents

- Preface

- Why Certifications Matter for Your Export Business

- Key Standards for Major Markets

- How to Get Certified in 5 Steps

- Quality Tests You Can’t Skip

- Common Mistakes

- Summary

Preface

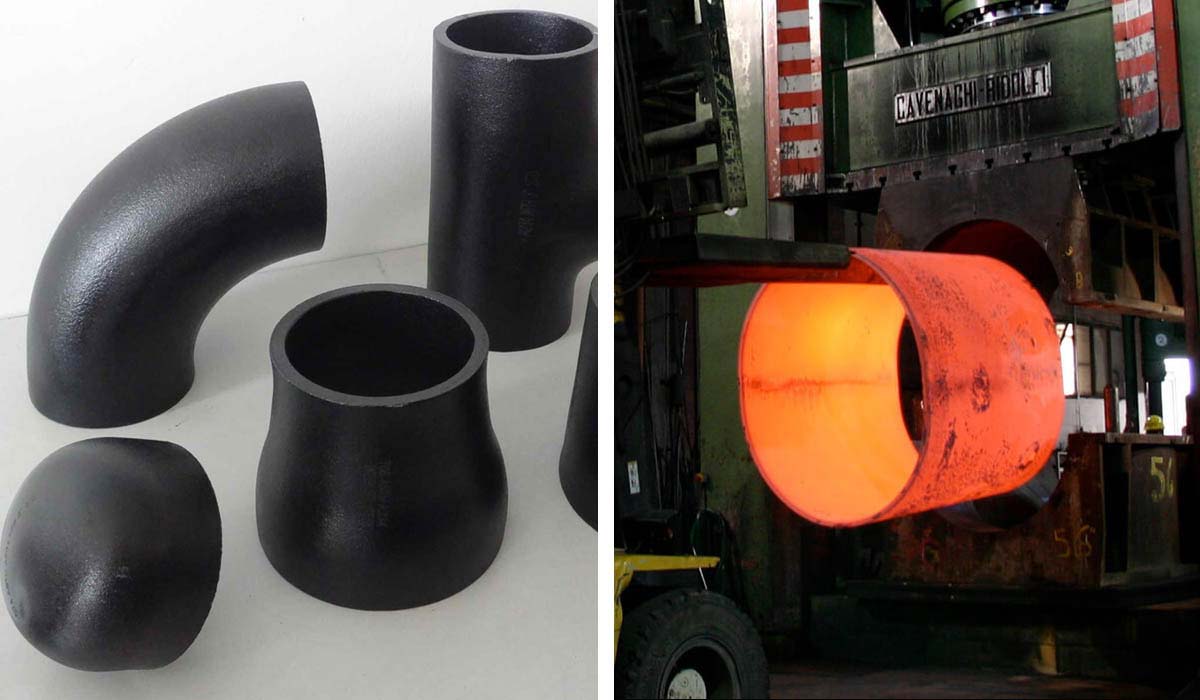

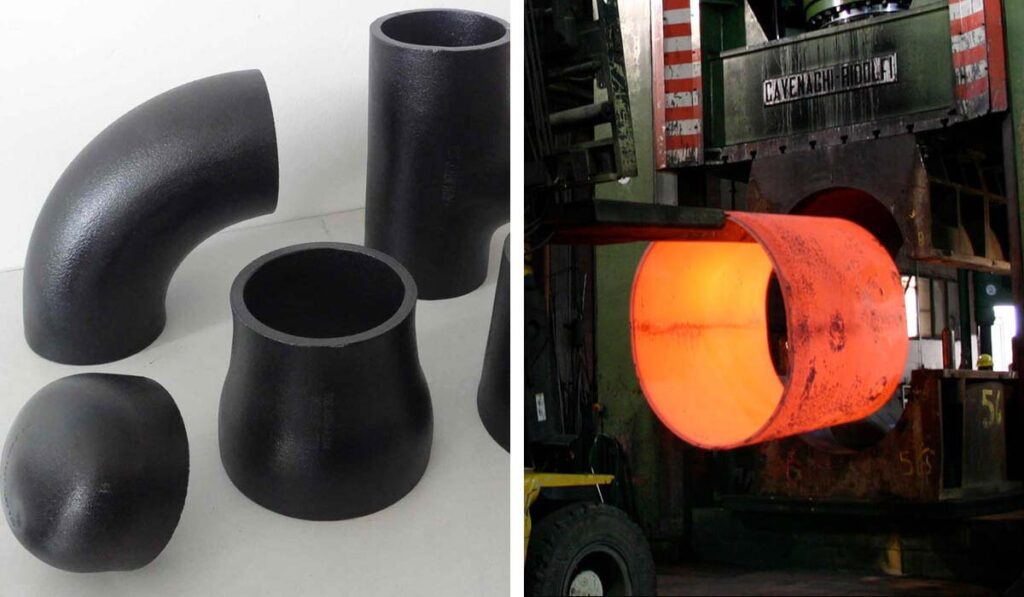

Learn the essential standards and certifications for exporting carbon steel pipe fittings globally.

Avoid costly mistakes and ensure compliance with EU, US, and Russian market requirements.

Why Certifications Matter for Your Export Business

Certification that meets international standards is crucial for customers and is also a guarantee for products.

In addition, the process of international standard certification is very strict and authoritative, which can be used as a reference for customers when purchasing.

Taking Metleader as an example, we have API testing certificates, ISO certification certificates and CCC certifications, which is one of the reasons why we can win the trust of many customers.

Key Standards for Major Markets

1. United States (ASME/API Standards)

To sell in the US, your fittings must follow ASME B16.9 (for welded elbows and tees) or ASME B16.11 (for forged socket welds). If you’re targeting oil and gas, API 6A certification is mandatory.

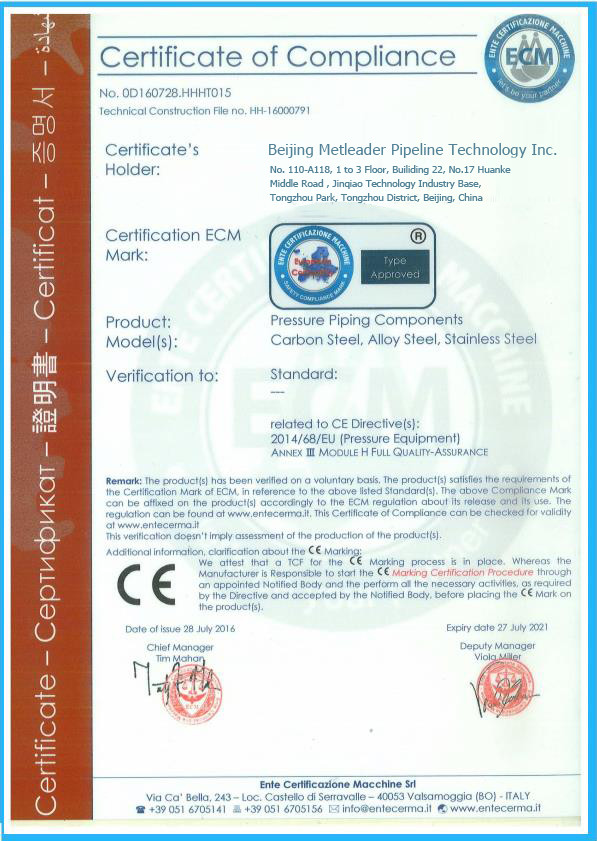

2. European Union (CE + PED)

The EU requires CE marking and compliance with the Pressure Equipment Directive (PED) for fittings used in systems above 0.5 Bar. Follow EN 10253 for butt-weld fittings and EN 1092 for flanges.

3. Russia & Eurasia (EAC Certification)

To access Russia, Kazakhstan, or Belarus, you need EAC certification (CU-TR). This ensures your fittings meet GOST 32569 standards.

4. Middle East (SASO)

Saudi Arabia requires SASO 2902 certification for pipe fittings. Tests include material checks and pressure resistance.

How to Get Certified in 5 Steps

Choose Your Target Market: Decide if you’re focusing on the US, EU, or others.

Test Your Products: Work with labs like TÜV (EU) or UL (US) to check materials, strength, and safety. For example, pressure-test fittings at 1.5x their rated capacity.

Prepare Documents: Gather material reports, welding records, and quality control plans.

Pass Factory Audits: Inspectors will check if your workshop follows ISO 9001 standards.

Renew Regularly: CE marks expire every 5 years—plan ahead to avoid gaps.

Quality Tests You Can’t Skip

XRF Gun Scans: Verify steel composition (e.g., ASTM A234 WPB should have 0.29-1.06% manganese).

Pressure Tests: Hold fittings under high pressure for 30 minutes to check for leaks.

Ultrasonic Testing: Use sound waves to find cracks or weak spots in welds.

Common Mistakes

Using Old Standards: Outdated norms like SN/T 0258.1-1993 are no longer valid. Switch to ASME or ISO.

Ignoring Updates: EU’s PED revised rules in 2024—check their website yearly.

Cheap Labs: Unaccredited labs might give fake certificates. Always pick TÜV, SGS, or UL.

Summary

This article focuses on the certification standards for carbon steel pipe fittings exports and why these certifications are necessary.

I believe these can provide some useful suggestions for carbon steel pipe fittings manufacturers and buyers.