Butt welding elbow knowledge detailed explanation: everything you need to know

Table of contents

- Preface

- What is a butt-weld elbow

- Butt-weld elbow splicing method

- Advantages and disadvantages of butt-weld

- Butt-weld elbow implementation standards

- Butt-weld elbow materials

- Socket welding VS butt welding

- Precautions for pipe elbow welding

- Summary

Preface

Butt-weld pipe fittings are used to change direction and connect to all necessary equipment and devices to achieve their functions.

Metleader offers a variety of butt-weld pipe fittings, including stainless steel pipe fittings, carbon steel pipe fittings, and various steel pipe products.

Butt-weld pipe fittings comply with ASME/ANSI B16.9 standards.

In engineering applications, butt-weld pipe fittings are very important. Today, through this article, we will introduce the basic knowledge of butt-weld pipe fittings, hoping to provide some help to beginners.

What is a butt-weld elbow

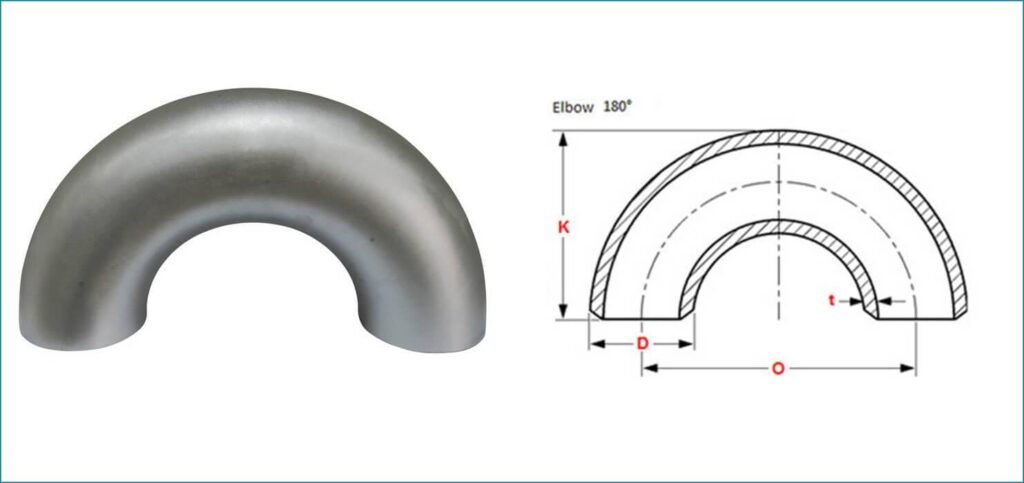

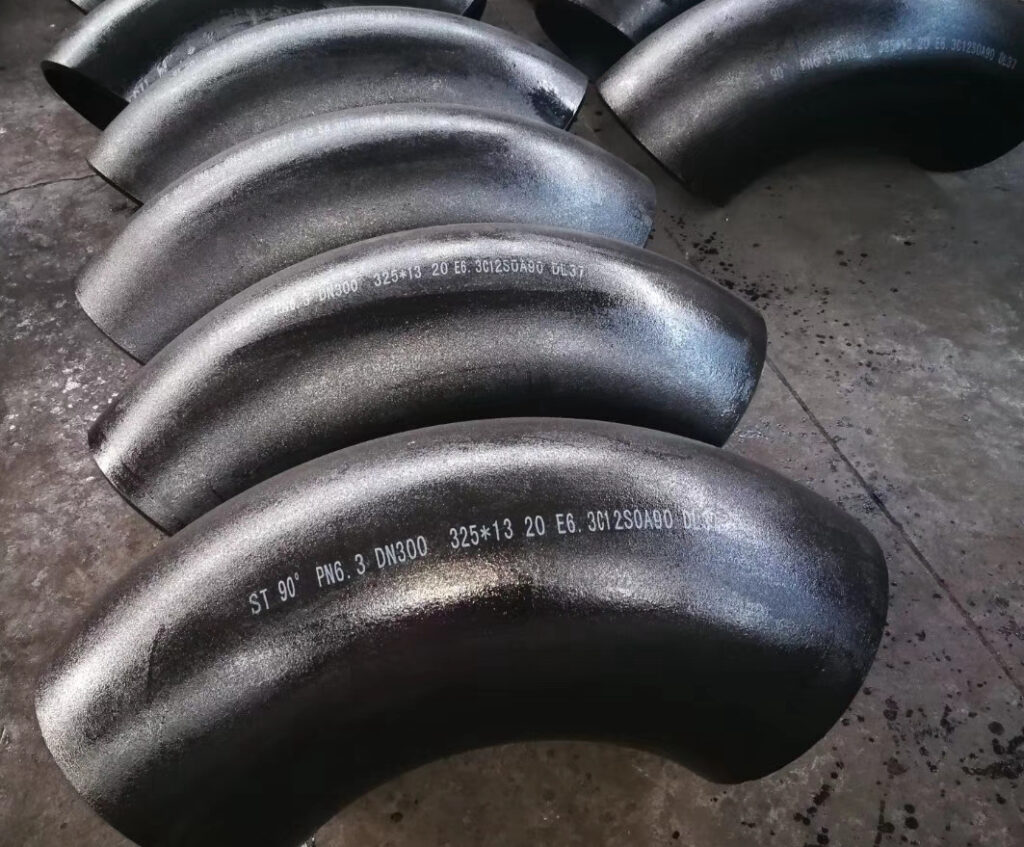

Butt welding elbow is a common pipe connection component, which is mainly used for the turning point of pipe connection, and can make the pipe turn at an angle of 90 degrees, 45 degrees or 30 degrees, etc.

Butt welding elbow is generally composed of two or more elbows, and is connected to the pipe through a butt welding joint, with tight connection and good sealing.

Butt-weld elbow splicing method

In some cases, pipes need to be spliced, and butt-welded elbows also need to be spliced. So can butt-welded elbows be spliced? The answer is yes, but you need to choose the right splicing method.

Below we introduce three splicing methods for butt-welded elbows:

Concentric reduction method

The concentric reduction method is a common butt-welded elbow splicing method, which is suitable for elbows with the same pipe diameter.

The specific splicing method is to first process the end faces of the two elbows into a circular concentric reduction surface, and then connect the butt-welded joints.

Intermediate corner method

The middle corner method is suitable for the case where the bending angles of the two elbows are the same.

The specific splicing method is to bevel the end faces of the two elbows at 45 degrees, and then connect them with a straight pipe of equal length.

The advantage of this method is that valves or other accessories can be installed on the straight pipe.

Module method

The module method is suitable for large pipes or situations where multiple elbows need to be spliced.

The specific splicing method is to assemble several elbows into a whole according to the number of elbows that need to be spliced, and then connect them to the pipe.

Advantages and disadvantages of butt-weld

Butt welding is a common way to install pipe elbows.

It fits the ends of two pipes together and then welds them with welding materials to form a continuous pipe.

Butt welding can be divided into two types: flat butt welding and shell-and-tube butt welding.

Advantages: Butt welding has a firm connection, compact structure, and does not create additional space.

Disadvantages: It is more expensive to manufacture and more difficult.

Butt-weld elbow implementation standards

ASME B16.9, GB/T12459, GB/T13401, GB/T10752, SH3408, SH3409, HG/T21631, HG/T21635, SY/T0510, JIS2311/2312/2313, DL/T695, EN 10253, etc.;

ISO 15590-2:2009 is a standard for butt-weld elbows for high-strength steel pipes. In addition, ISO has developed other standards, such as ISO 15590-1 and ISO 15590-3, for different types of butt-weld elbows.

ANSI B16.9 is a commonly used standard, which includes elbows, tees, pipe caps, and pipe flanges. In addition, ANSI has developed other standards, such as ANSI B16.49, which provides detailed requirements for the design and manufacture of elbows.

EN 10253-2 is a commonly used standard that applies to the design and manufacture of welded elbows. In addition, EN has developed other standards, such as EN 10253-3, to provide requirements for elbows for special purposes.

Butt-weld elbow materials

Butt welding elbow materials include carbon steel, alloy steel, stainless steel.

The choice of material depends on the application that the butt welding elbow will be used for.

For example, in high temperature and high pressure piping systems, alloy steel or stainless steel that can withstand high temperature and high pressure is required.

Socket welding VS butt welding

Socket welding, also known as clamp welding, is a method of inserting a pipe into a quick connector with a sleeve and a socket by using a pipe fitting, and fixing it on the quick connector for welding.

Compared with butt welding, the disadvantage of socket welding is that a certain number of quick connectors need to be replaced, and there may be bulges at the connection.

Butt welding is a method of aligning the pipes, aligning the elbows at the ends of the two pipes, and then connecting them.

Its connection method is more stable than socket welding and is less prone to air leakage.

Precautions for pipe elbow welding

Before welding the pipe elbow, it is necessary to check whether there are impurities such as grease, dust, etc. on the surface of the pipe elbow, and clean it before welding.

When choosing the welding method of the pipe elbow, the material, shape, weight and working environment of the pipe should be considered, and the welding cost and efficiency should also be considered.

For the butt welding of large pipe elbows, the skylight method can be used for welding.

The welding of pipe elbows needs to protect the surrounding environment, on the one hand to prevent other workers from being injured, and on the other hand to prevent welding materials from polluting the environment and even causing safety accidents.

Summary

Butt welding elbow is a common connection method in pipeline system. To ensure the quality and safety of butt welding elbow, butt welding elbow must meet the technical requirements of the project and international standards and specifications.

Butt welding elbow is widely used in various pipeline systems, including oil, natural gas, chemical, electric power, shipbuilding and shipbuilding.

This article mainly introduces some knowledge about butt welding elbow, which I believe can provide reference and help for beginners.

As a 43-year manufacturer of pipeline accessories, Metleader has mature experience in production technology and can ensure product quality.